Topex Multi-fit Snow Wiper Blade T-X8-W

Topex Multi-fit Snow Wiper Blade T-X8-W

SKU: T-X8-W

Key Features:

Application: 98% cars.

Size: 12″~32″

Structure: Double Spring Inside for enhanced pressure distribution.

Material: High Carbon Steel + 100% Natural Rubber with Teflon Coating

Quality: IS0 9001 Certificated,

Guarantee: 1 Year

Diver side: Left/Right

Trusted All-Weather Multi-Fit Snow Wiper Blade Expert Producer

| Wiper Type | Multi-Fit Snow Wiper Blade |

| Brand Name | Topex |

| Place of Origin | China |

| Model No | T-X8-S |

| Size: | 12″-28″ |

| Car Make | 98% of Cars |

| Color | Black |

| Material | High Carbon Steel, AAA-Class Natural Rubber with Teflon Coating |

| Performance | -40°C to +70°C, ideal for extreme cold climates |

| Warranty | At least one year |

| Quality | 100% Professional Test with 1,000,000-cycle durability |

| Package | Color Box, Blister Card, PP Box (Accept customized logo), 50pcs/carton |

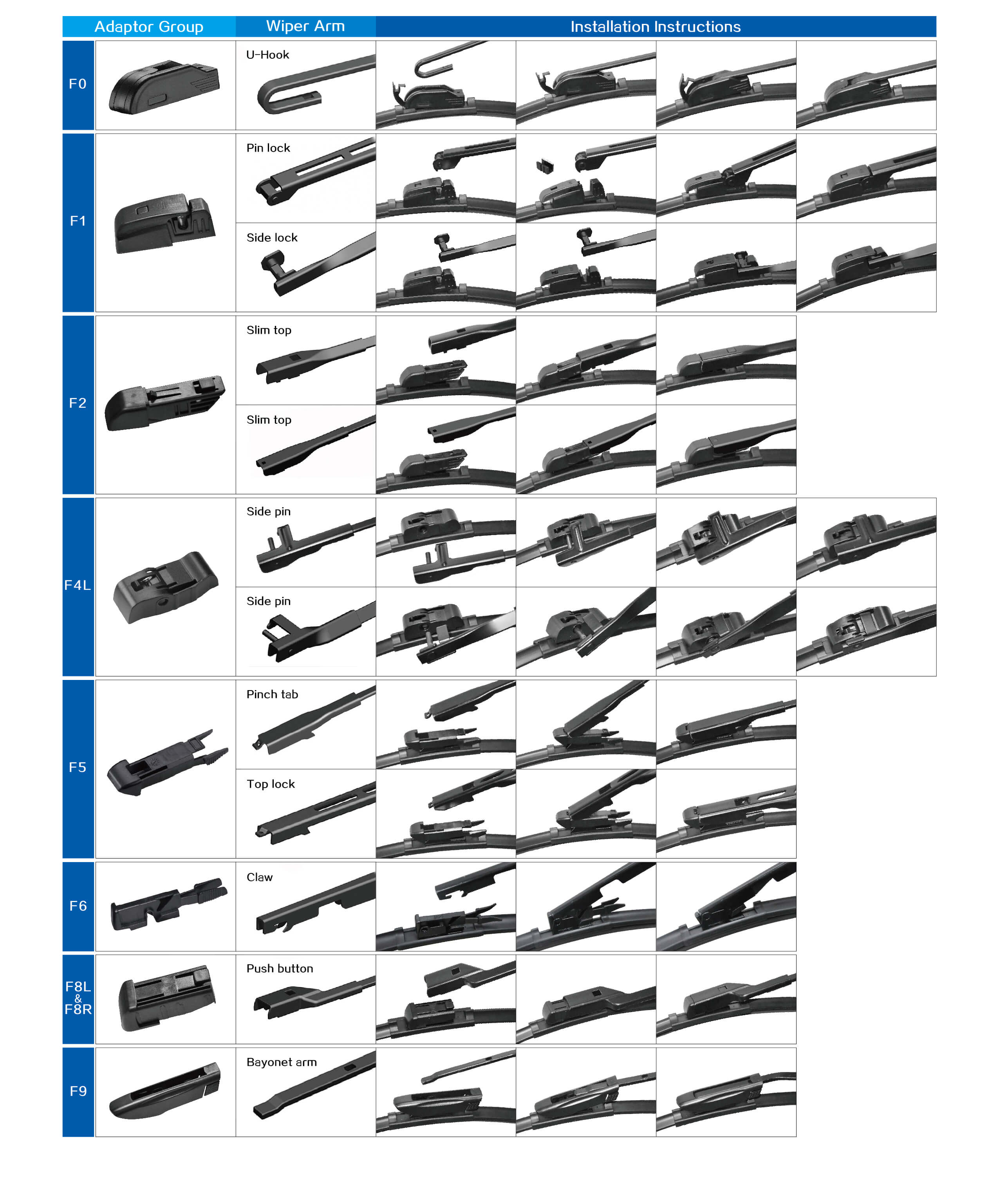

| Adaptor | Multi-Cap in, for 98% vehicle coverage |

| Choice | Right-Hand Driving & Left Hand-Driving |

| Certificate | ISO9001 |

Advantages

Advantages of T-X8-W Multi-Fit Snow Wiper Blade

Frost-Resistant

Blocks ice buildup with sealed EPDM covering, ensuring reliable wipes in -40°C blizzards.

Snow-Clear

Delivers streak-free visibility through heavy snow, with Teflon-coated rubber for flawless coverage.

Wind-Silent

Operates quietly in gusts, minimizing noise for stress-free driving in stormy conditions.

Extreme-Durable

Endures 1,000,000+ wiping cycles with SGCC steel, lasting 1+ year in harsh winters.

Package

We offer versatile packaging solutions for the T-X8-W Multi-Fit Snow Wiper Blade, including custom boxes, neutral packs, and blister displays. OEM and private labeling are fully supported.

Package

Package Material

Inner Box

Master Carton

Quality Control

We offer versatile packaging solutions for the T-X8-W Multi-Fit Snow Wiper Blade, including custom boxes, neutral packs, and blister displays. OEM and private labeling are fully supported.

| Test List | Condition | Methods | Point |

| Initial Wiper | Temperature: 20°C± 15°C

Humidity: 65°C± 20°C Water temperature: Less than 38°C After 10 cycles up and down, Min.8 point |

After 10 cycles up and down and judge after 3 sec.

Wipe grade must be above min 8 point |

8~9 |

| Durability Test | Temperature: 20°C± 15°C

Humidity: 65°C± 20°C Water temperature: Less than 38°C After 500,000 cycles up and down, Min.5~6 point |

Continuous wipe 500,000 cycles up and down and judge after 3 sec.

Wipe grade must be above min 5~6 |

5~6 |

| Corrosion Test | Concentration of Salt Water: 5°C± 1°C

Temperature: 35°C± 2°C Test Time (Hours): Follow Customer request |

It must be no red rust on the surface | (126 Hr)

No Rust |

| Ozone Test | Concentration of Ozone: 50ppmh

Temperature: 35°C± 2°C Stretch rate: 20% Test Time (Hours): 72 hours |

It must be no crack on the surface after testing | No Crack |

FAQ

FAQ for Topex T-X8-W multi-fit snow wiper blade

What vehicles does the T-X8-W Multi-Fit Snow Wiper Blade fit?

The T-X8-W fits 98%+ of cars in Russia, Japan, North America, and Northern Europe, including sedans, SUVs, and light trucks, with multi-clips for U-Hook, Pinch Tab, and Bayonet arms. Check our fitment tool or consult our team for make/model/year specifics. Ideal for OEM/aftermarket needs in cold climates.

How long does the T-X8-W Multi-Fit Snow Wiper Blade last?

With AAA-Class natural rubber and Teflon coating, the T-X8-W offers a 10–12-month guarantee under normal conditions, enduring 1,000,000 wiping cycles and resisting -40°C cold for streak-free performance. Regular cleaning extends life up to 18 months. Backed by ISO 9001/TS16949 standards for reliable durability. Contact us for testing data.

Can Topex customize the T-X8-W Multi-Fit Snow Wiper Blade for OEM/ODM?

Yes, Topex provides full OEM/ODM services for the T-X8-W, including logo engraving, custom packaging, and cold-resistant material tweaks. Our 40+ patents ensure tailored designs for 60+ countries. Flexible MOQs start at 2,000 units per size.

What is the MOQ for wholesale T-X8-W Multi-Fit Snow Wiper Blades?

Topex offers flexible MOQs from 2,000 units per size (total 30,000pcs) for the T-X8-W, with competitive bulk pricing and 20–30-day lead times from Xiamen port. Our 600,000pcs/month capacity supports global distributors. Free samples available for qualified buyers.

How does Topex ensure T-X8-W Multi-Fit Snow Wiper Blade quality?

Every T-X8-W undergoes SAE J903 testing (500,000+ cycles), thermal cycling (-40°C to +70°C), and ozone resistance checks, with 100% sealed EPDM covering and SGCC steel for corrosion resistance, certified by ISO 9001/TS16949. In-house labs guarantee defect-free production.

After-sale Service

We are committed to providing customers with comprehensive, timely, and professional

support and assistance to ensure customer satisfaction with our products and services.

After-Sales Consultation

Customers can contact our after-sales service team via phone, email, online chat, etc., to raise questions or requests.

Technical Support

Our technical team provides professional technical support to answer customer questions regarding product installation.

After-Sales Training

For customers in need, we can provide product usage training and technical training to help customers improve .

Technical Support

Our technical team provides professional technical support to answer customer questions regarding product installation.

After-Sales Tracking

We maintain regular contact with customers to understand the product usage situation and gather customer.

After-Sales Satisfaction Survey

After completing the after-sales service, we send a satisfaction survey question-naire to customers to understand their.